Father

Professional

- Messages

- 2,602

- Reaction score

- 837

- Points

- 113

Technologies:

Technology of applying any selective image (logo, graphics, etc.) with a liquid varnish that polymerizes under the influence of UV rays with accurate contour preservation.

Selective varnishing is a popular method of elite finishing of plastic cards. Crystal glossy image allows you to enjoy the play of light highlighted design elements on discount, gift, business and other plastic cards.

An exquisite coating with various special effects makes a vivid impression on customers and business partners, leaving pleasant associations about your company.

The paint outline must overlap the image by at least 0.3 mm.

The minimum thickness of the space element must not be less than 0.3 mm.

Our vast experience allows us to achieve excellent results and get a really voluminous varnish with a relief that is noticeable with tactile contact.

The main technology for printing large print runs of all types of plastic cards. This method of printing is characterized by high clarity and brightness of a full-color image, obtaining even the smallest details of the drawing and high-quality micro-rifts.

The paint of the offset machine is fed to the offset shaft with photosensitive film (photo molds). The film serves as a template for transferring the layout image from one offset shaft to another, and then onto the plastic sheets of future cards.

UV - illuminated parts of the mold begin to attract water and repel any oily substance (paint). The remaining (unlit) parts of the forms begin, on the contrary, to repel water and attract paint. Thus, the paint is transferred only to the areas of the mold that are absorbed by water, forming letters and images.

The offset shaft contributes to less mold wear and greater evenness of the paint.

In offset technology, we use two printing methods with the use of:

Any color in full-color printing (CMYK) is achieved by mixing 3 colors (triad) of the main color-cyan( Cyan), magenta( Magenta), yellow (Yellow) and key color (KEY), usually black (Black).

It is with full-color printing (CMYK) that you can get a realistic image with a large number of shades.

CMYK colors always require the use of four photo forms, and sometimes additional forms for obtaining plastic cards with increased requirements for visual characteristics. When the exact color of a uniform fill is required to reduce the cost of photo forms, Pantone mixed paints come to the rescue.

Pantone-derived paints allow you to get colors and shades of certain areas of the spectrum (blue, green, brown) that go beyond the CMYK color range, which is widely used by companies around the world to brand their products or logos with the "corporate" color. Pantone mixed paints are tinted in advance by the number in the catalog and come to us ready-made, eliminating errors in obtaining colors from the four colors on the cards, and saving on color tests. Competent and skillful use of such tools as mixed paints by the designer can both reduce costs (in some cases) and get a visually more spectacular result.

Our design department can advise you on how to correctly and skillfully use ink in offset printing and prevent unnecessary costs. To get an excellent result, we will help you take into account all the subtleties of the technology when developing a layout and preparing an order for printing.

Fast printing of high-quality images (text, graphics,drawings, photos) to a plastic card directly from a computer system without prepress preparation.

Plastic cards are printed on inkjet printers and have a number of advantages:

Silk screen printing (silkscreen printing) - screen printing, in which” layers " of paint are applied to the surface using a squeegee through a screen grid.

We use silkscreen printing to create spectacular relief images (logos, graphics, etc.) and backgrounds on your plastic cards, as well as for applying selective varnishing, signature strips, and scratch panels.

In those places where the paint should not pass in the illuminated grid , a film is formed that serves as a stencil for us. The grid is washed off with plain water, dried and installed on the equipment for running paint with a rubber squeegee.

By rearranging the grids with different colors, we achieve the final result - getting another bright masterpiece inherent in silkscreen printing.

The silk screen printing machine allows you to paint sheet plastic in any desired color, which is then printed with CMYK or Pantone paints.

Most often, interesting backgrounds for your plastic cards are achieved in this way - metal backgrounds of different colors and shades, gold, silver, mother-of-pearl, with 3D effects, glow-in-the-dark and thermochromic, changing their color depending on the temperature.

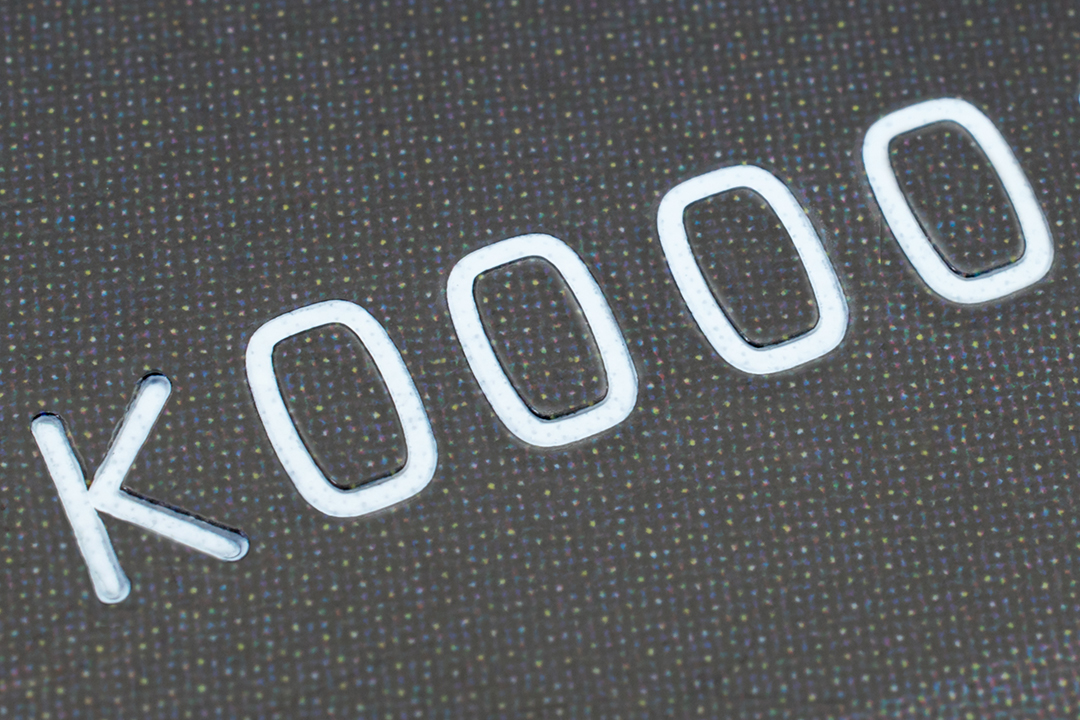

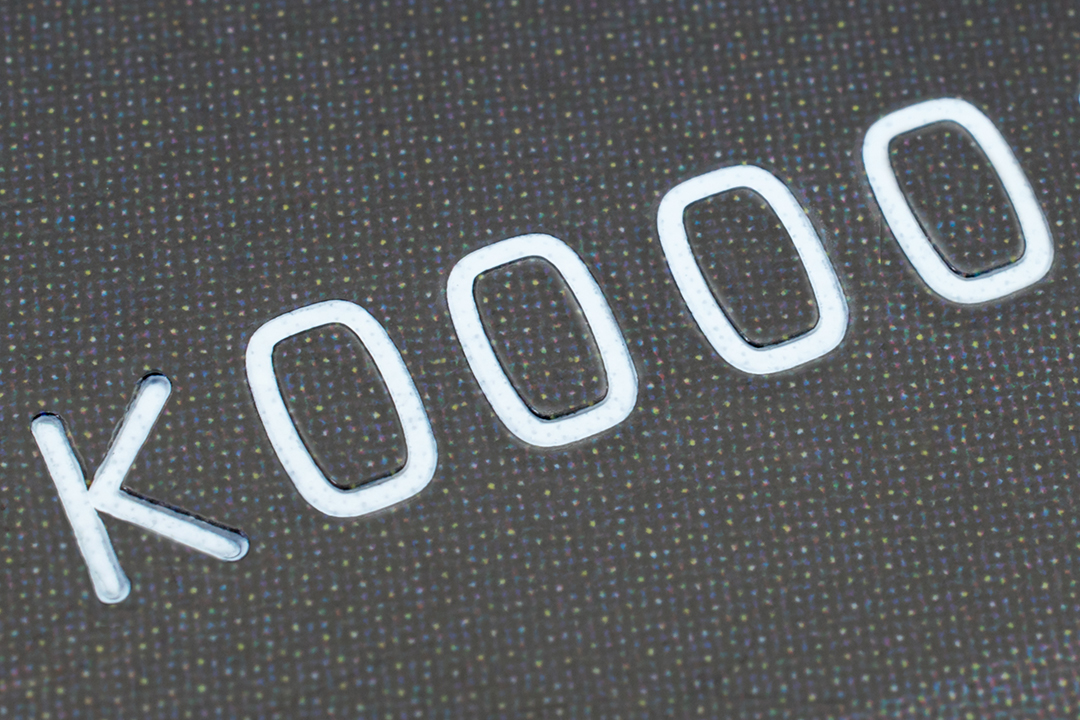

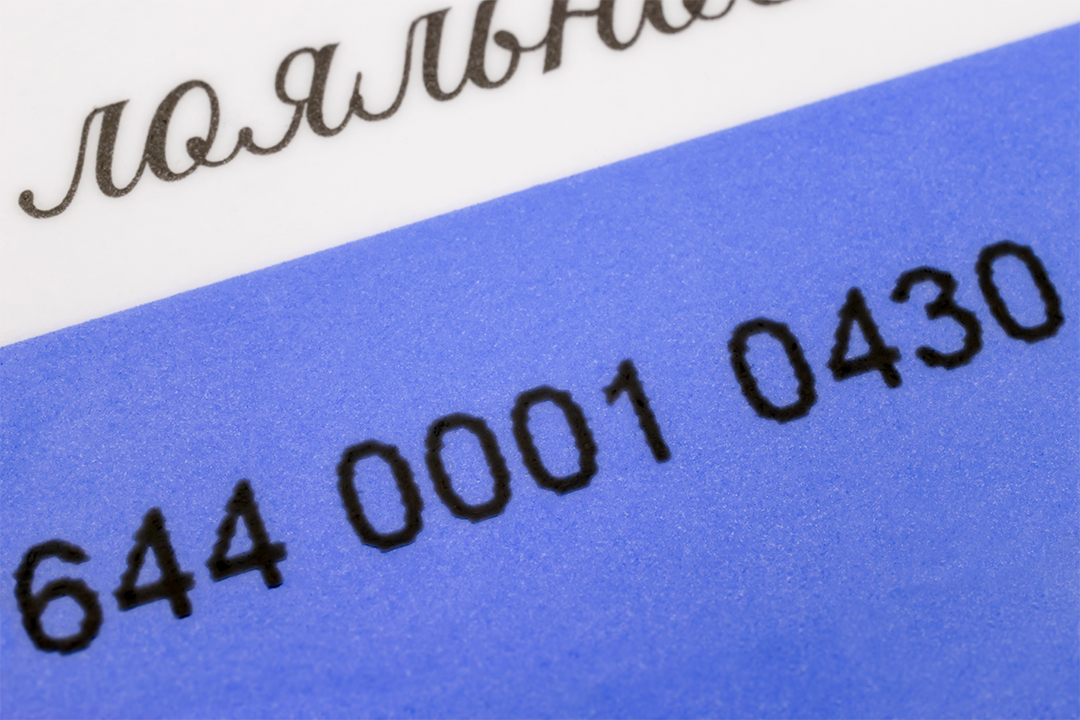

Embossing is the process of mechanically squeezing out various information on the front side of a plastic card (the last name, first name and patronymic of the holder, validity period, card number, company name (for corporate clients)).

A stylish card decorated with various emblems, iridescent embossed signs, inscriptions made up of convex shiny symbols can serve not only as its protection, but also become a bright addition to the design of the company's corporate identity.

Automatic embossers are a complex technical complex that includes a microcomputer that controls a drum with a set of letters (Cyrillic, Latin or numerals), through which images on plastic cards are squeezed out.

The productivity of such devices can reach several hundred personalizations per hour.

The process is strictly regulated and has clear requirements.

The symbols stamped on the card must be located on the card at a distance of at least 5 mm from the top, at least 5 mm from the bottom edge of the card, and at a distance of at least 8 mm from the left and right edges of the card. The distance from the magnetic strip should not be less than 5 mm.

When you emboss characters, they are only pressed horizontally and have a standard font size of 3.5 x 4.5 mm and 2.5 x 3 mm.

A large font can only contain numbers: 0123456789

Small font - numbers and uppercase letters of the English alphabet, including symbols: ".", ",", " ’", "-", "/", "&"

The number of characters in one line is:

Pressed letters and numbers can be colored in color, this procedure is called "typing". For tipping, gold or silver foil is most often used, less often black or white, but other colors are also possible.

Mechanical indentation of variable data (expiration date, card number) on the front side of a plastic card, usually with further coloring (tipping) in black or white.

For the best solution of your tasks, you can combine the types of personalization.

Indented symbols must be located on the card at a distance of at least 5 mm from the top, at least 5 mm from the bottom edge of the card, and at a distance of at least 8 mm from the left and right edges of the card. The distance from the magnetic strip should be at least 5 mm.

When indent printing, characters are pressed only horizontally and have a standard font size of 3.5 x 4.5 mm and 2.5 x 3 mm.

A large font can only contain numbers: 0123456789

Small font - numbers and uppercase letters of the English alphabet, including symbols: ".", ",", " ’", "-", "/", "&"

The number of characters in one line is:

Indented letters and numbers can be colored. This procedure is called "typing". For tipping, black or white foil is most often used.

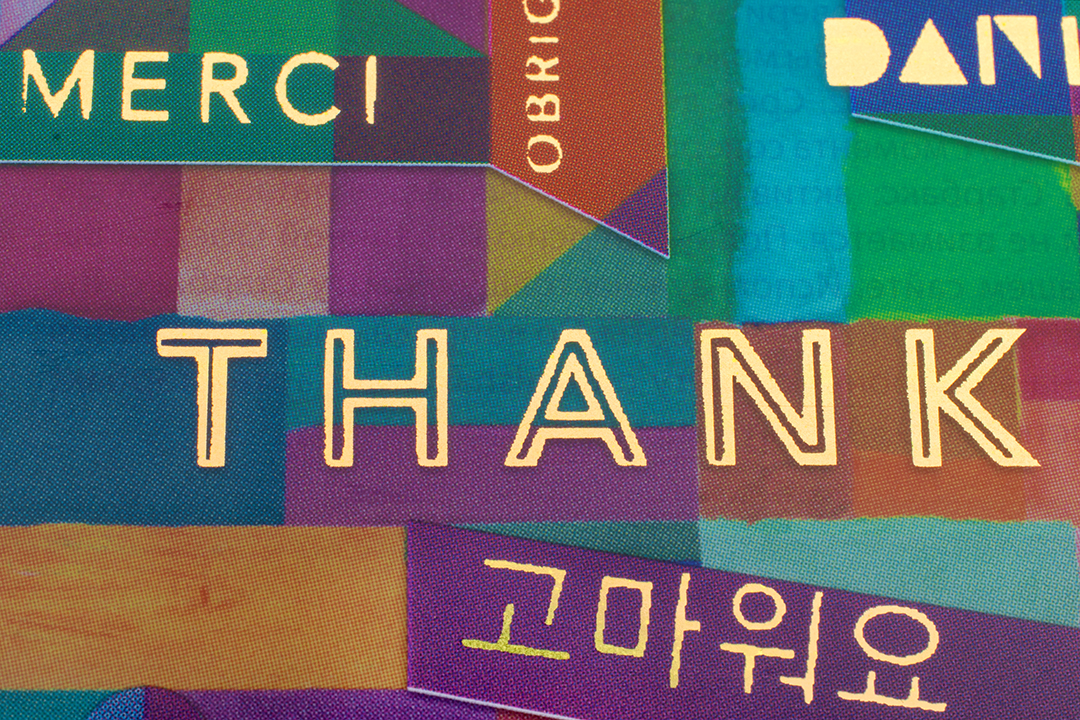

The technology of applying a selective image with ordinary or holographic foil, to get a metallic luster of various colors and shades (gold, silver, etc.) and give a luxurious appearance to your corporate identity on the card.

Metallic elements of the impression (logo, company name) attract attention, and the relief that can be obtained by hot stamping emphasizes their sophistication, which makes it possible to effectively highlight parts of the image containing important information.

Embossing refers to the post-printing finishing of products and is already done on the finished (laminated) surface of the card.

Foil is placed between the stamp and the plastic card. The cliche is heated to the desired temperature and pressed against the foil under the influence of strong pressure.

The visual possibilities of embossing are very wide-combinations of different textures, colors and types of foil provide a huge number of original design options.

.jpg)

View all kinds of cards

Choose your own color and texture just for your unique style!

Holographic foil is becoming increasingly popular in the decoration of plastic cards. It has mechanical resistance and opacity. It is used to give prints a memorable look and increase the degree of protection against forgery.

For small print runs, it is more profitable to replace the stamping with sublimation printing with metallized foil. As a rule, customers highlight numbers, symbols, and letters (in gold or silver). The quality of this method is slightly inferior to hot stamping, sublimation printing is not as durable in use as with hot foil pressing, but it saves the cost of cliches.

For regular foil stamping, when placing an item in the layout, you need to take into account the field on the card, the indent should be:

For stamping with holographic foil, it is necessary to position each hologram more clearly relative to the image before printing with an accuracy of 0.1-0.2 mm.

Therefore, special presses with complex drive control systems are used for their pripressovki. Accuracy is achieved by using labels on the foil.

When you emboss text, there is a font size limit. For personalization elements, you must specify the font name, font style, and size. The text must be at least 6 pt (for the Bold style), and at least 10 pt (for the Normal style).

Stamping is used on plastic cards with a thickness of 0.65-0.84 mm. Embossing on thin cards can cause it to slightly deform.

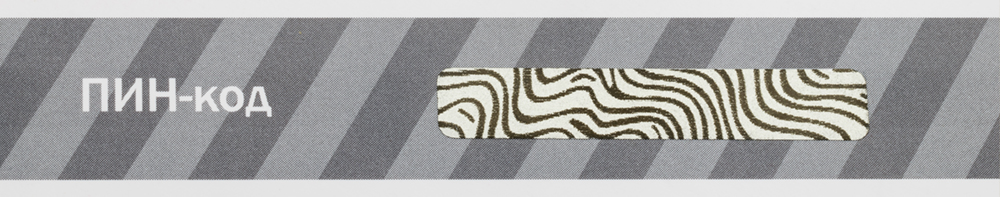

A special layer on a plastic card that protects secret data: text (code or word), drawing.Information under the scratch strip is only available when it is destroyed (erased).

Intrigue for customers under the erasable scratch card layer in a new promotion in an exciting way will be a win for your business. It will attract customers and create a loyal customer base, increasing the firm's revenue.

Use different forms of scratch fields on your cards to make your client more interested.

Scratch coating is applied in two ways: silk screen printing with special ink and scratch stickers.

The complexity of the pattern does not affect the cost of work. The price increases only if the scratch field increases by more than 30% due to additional paint consumption.

The font and size of the scratch strip can be any.

Our experts will help you choose the best way to apply a scratch strip.

A special strip is designed for writing a signature sample and other personal information with a ballpoint pen, which serves as an additional protection for the card when identifying its owner.

We can create a special layer of any configuration, almost all over the card surface on both sides, with the following restrictions:

On cards with a magnetic stripe, do not place the signature panel in the rental area of the reader head - this may lead to clogging of the reader and damage to the signature strip itself.

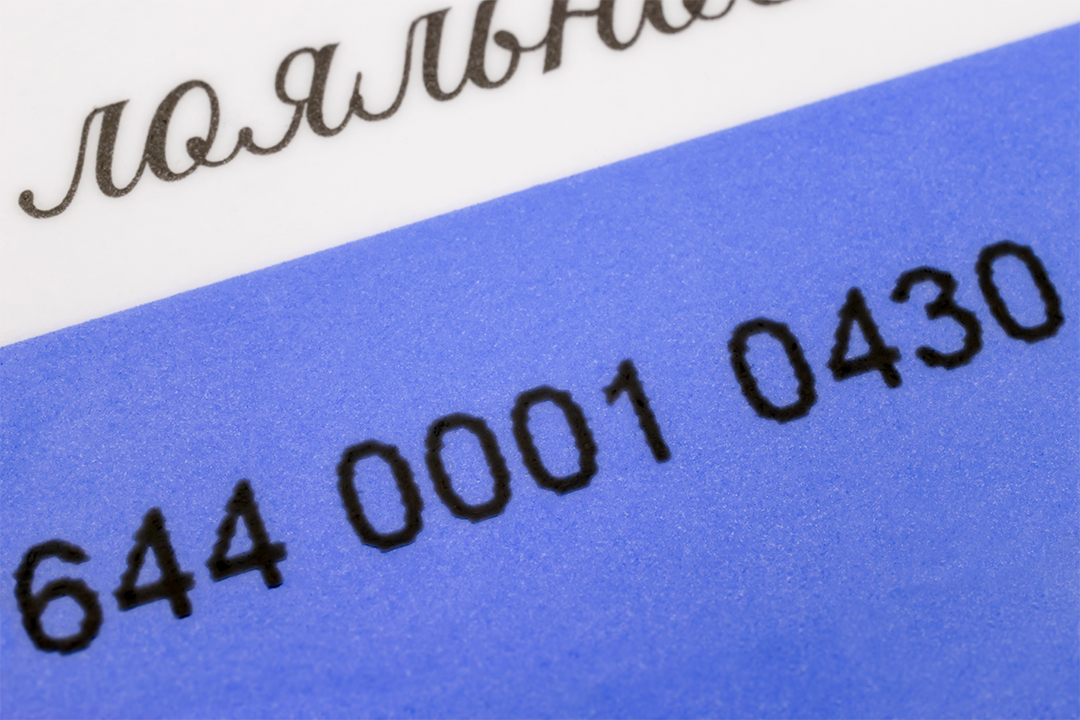

Print individual variable data (last name,first name, card number, date of birth, position,phone number) on the card surface to identify the owner.

Variable data is relevant when using discount, bonus, club cards, badges, and passes.

Sublimation printing is traditionally the most expensive and less productive, but setting up the equipment takes only a few minutes, which makes this method optimal for small and urgent print runs.

If we are talking about several tens or hundreds of thousands of cards, then drip-jet and DoD printing come to the rescue.

Drop-jet marking is performed by a drop-jet printer at very high speeds. This method is used to plot, for example, the date of manufacture of food products. A characteristic feature of this method is the visible dots that make up the symbols.

DoD printing is done with an expensive personalization package. Inks that harden under UV light are used, which makes the image resistant to any mechanical and chemical influences, unlike the above methods, the image of which can be erased over time.

Each card can contain an unlimited amount of variable information. End-to-end variable data (1-2-3-4-5, etc.) can be specified with a range. For example: 0001-0500.

More complex variables (out of order or multiple corresponding variables) must be provided as an Excel electronic database.

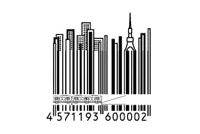

Small-volume graphic information on plastic cards for customer identification. Easily read by all kinds of scanners and apps in your phone.

Plastic cards most often display a barcode: EAN-13, EAN-8, Code-39, Code-128. The choice of the appropriate option depends on your card usage conditions.

A barcode can be applied using any printing method and encoded in only one direction (in width, the more information, the wider the barcode).

The amount of information in a linear barcode does not affect the height of the barcode. However, the higher the barcode, the more likely it is to be read the first time.

It is possible to place the barcode on the card in horizontal and vertical versions and stripes of contrasting colors depending on the selected design. Printing in black on a white or red background provides a more stable reading experience.

We can help you determine the type of barcode that is convenient for your account system. For consultation and ordering, please contact our managers online.

Used instead of ELAN 13 if there is not enough space on the card. You can write a 7-digit number, and the 8th digit is a control number.

The most popular format. You can write a 12-digit number, and the 13th digit is a control number.

CODE 39 is a widely used barcode. Demanding of free space.

You can encode from 1 to 70 characters. You can use Latin letters (from A to Z from a to z), numbers (from 1 to 0), and special characters:

(! @ # $ % ^ * ( ) - + = _ |\/ [ ] { } . , ; :' ` " )

You can encode from 1 to 43 characters. You can use Latin letters (from A to Z), numbers

(from 1 to 0), and special characters:

(+ - . % $ space)

Attention: when developing the layout, you need to specify the location for placing the barcode in the form of a white rectangle. If the card background is light, then you can mark the card without using a white background. The barcode size must be at least 34 x 14 mm and no closer than 2.5-5 mm from the edge of the card.

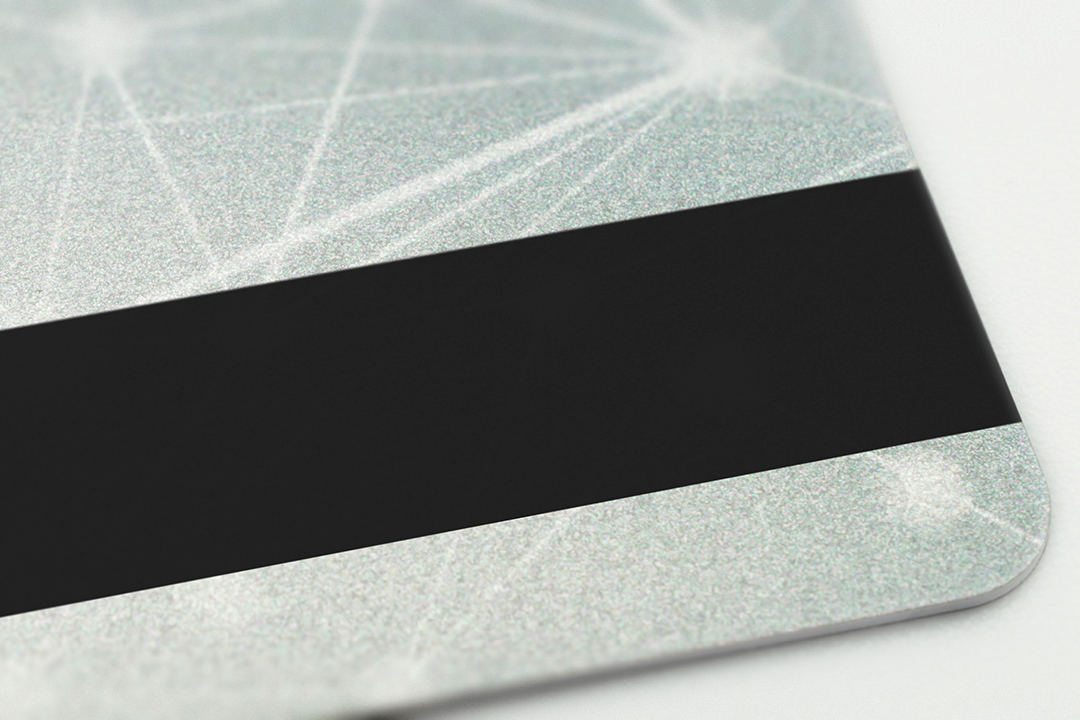

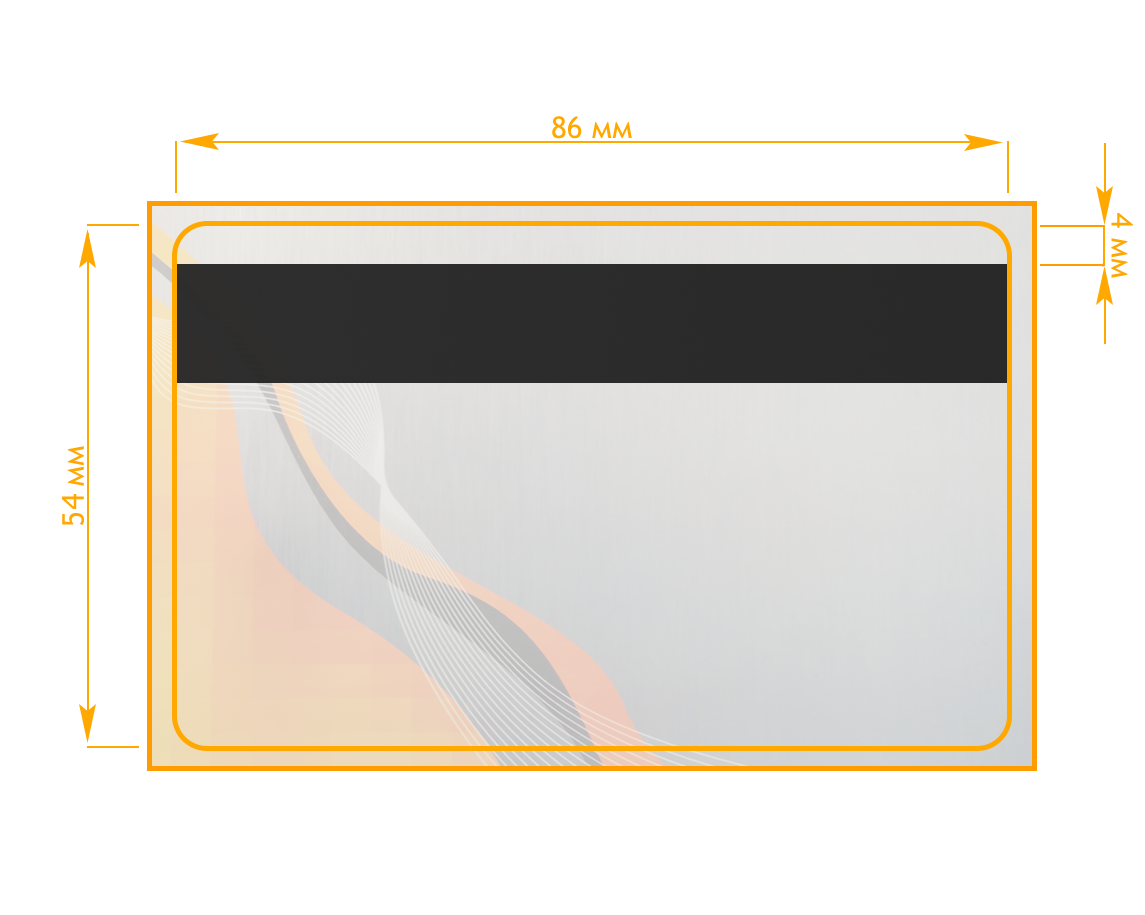

Flexible tape for storing data (data storage medium) serving as a cardholder identifier.

The magnetic stripe is programmed for specific tasks and is easily read using standard devices (card readers) that can transfer data to a computer in 1 second.

Sometimes card readers are programmed using an algorithm that differs from the standard one. In this case, the device can only read information from certain cards that use the same algorithm for recording.

The stripe is applied to cards that meet ISO standards - discount, gift, social, business cards, electronic keys and identity cards of employees in organizations.

Your data is stored on it longer than on the Lo-Co band under the same conditions of use, so they are plotted on cards designed for long-term and frequent use.

The Lo-Co band is usually used on temporary access cards, for example, in hotels as electronic keys. Lo-Co card magnetization requires less expensive equipment. It is noted that magnetic bands with low coercivity are colored light brown, and bands with high coercivity are almost black.

Although the color of the strip can be any, it depends on the manufacturer of the tape. The color does not affect the quality. You don't have to limit your imagination, we are ready to make a card with a silver, gold, blue, red, and green stripe for you.

Data is written (or encoded) to the card at the client's request once and is not rewritten again.

In plastic discount cards or electronic keys, either one second track is used, or the first and second. All three tracks are mainly used on banking system cards.

The band is encoded with:

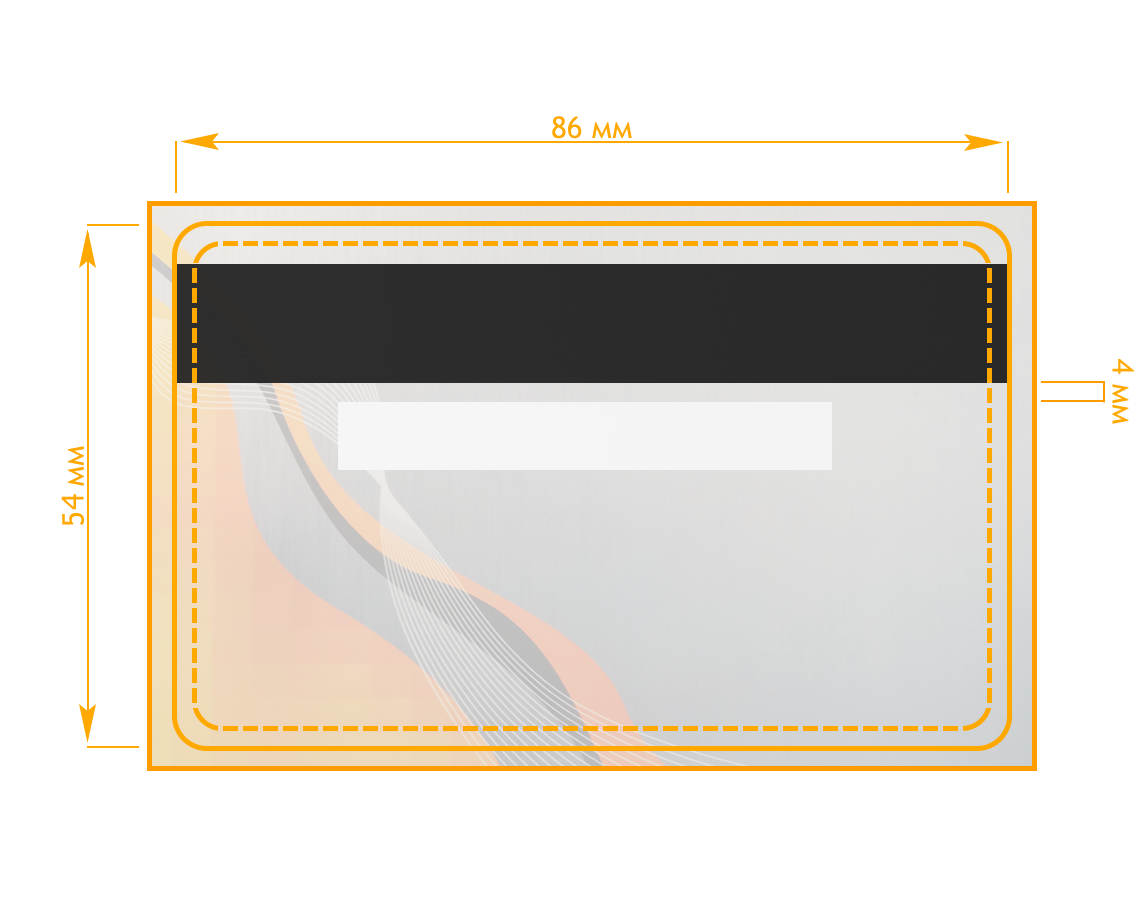

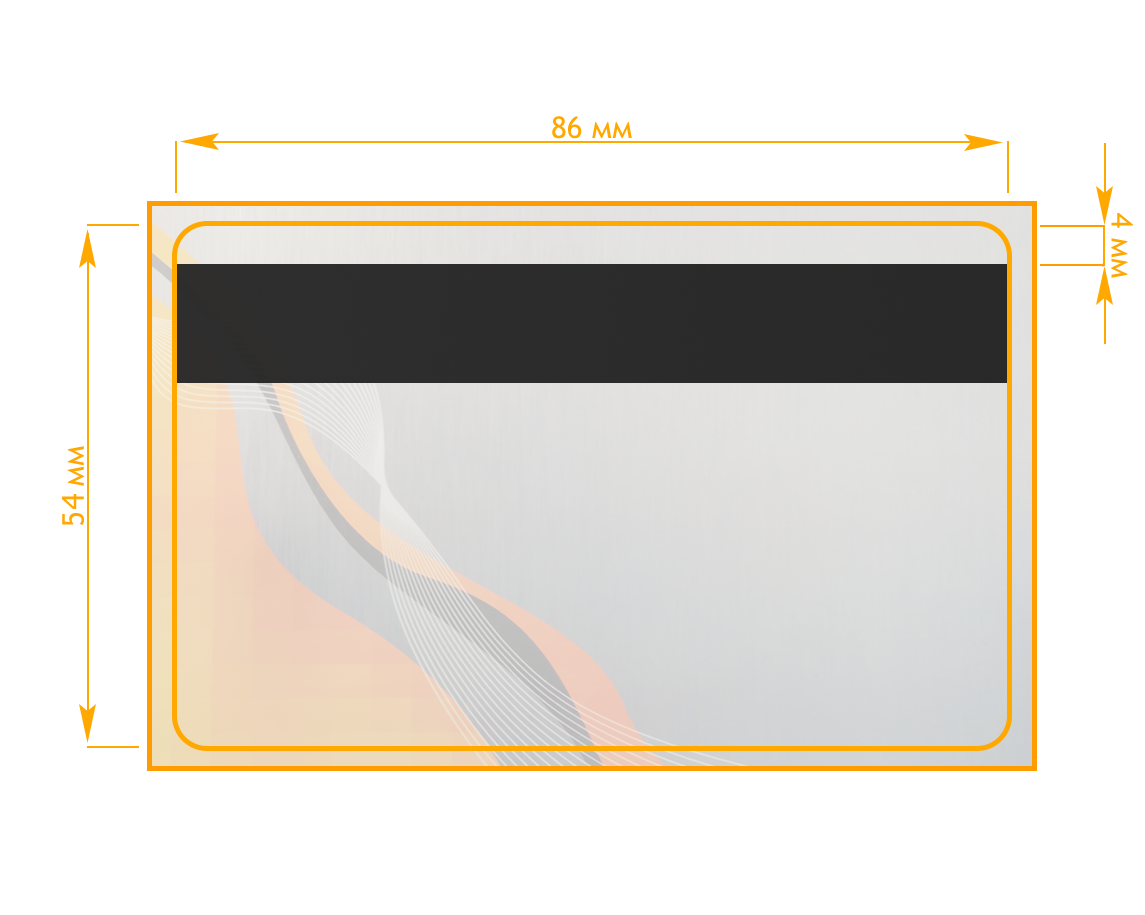

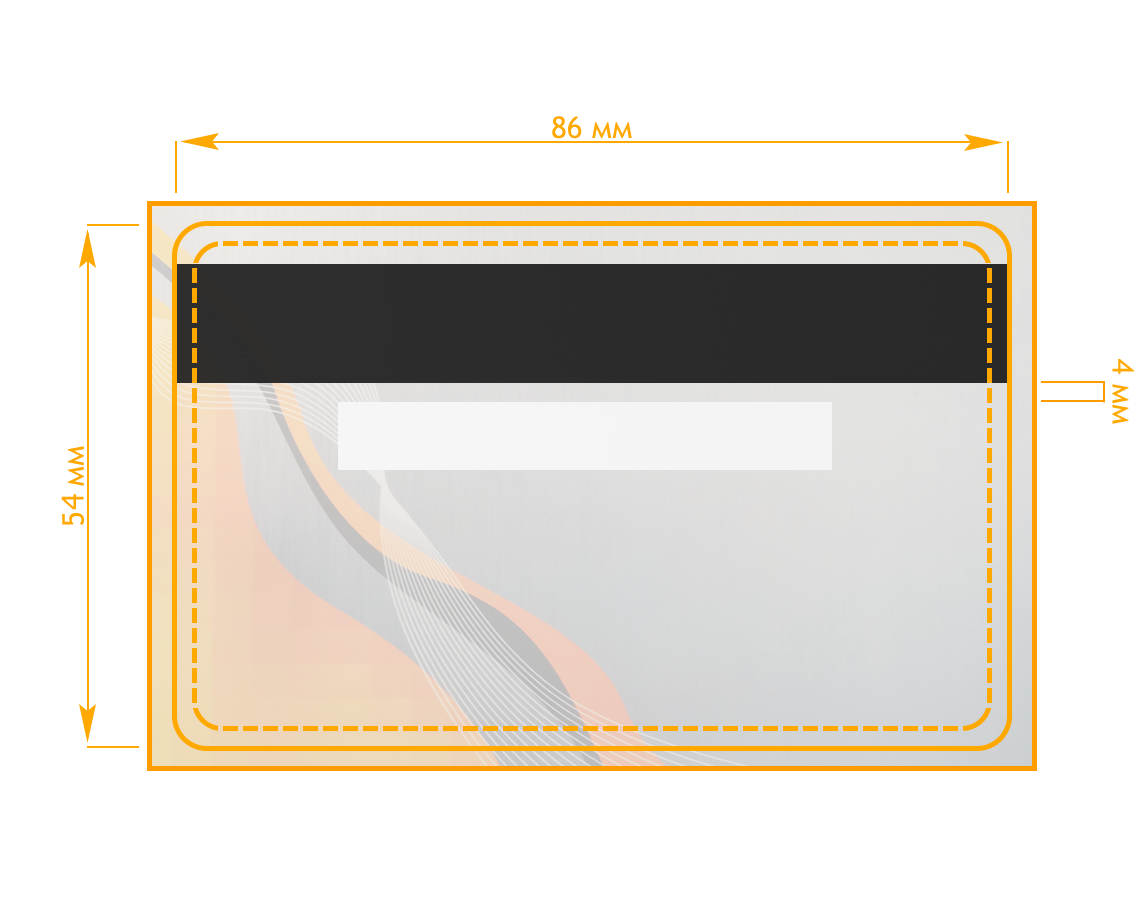

For standard readers, the magnetic stripe is made 12.7 mm wide. According to the ISO-7811 quality standard, you can also use a narrow, 6.35 mm magnetic strip, but a narrow strip is cheaper because you can only record the second track on it.

Both strips can be positioned strictly 4 mm from the upper and lower edges in a horizontal position.

Electronic personalization - recording individual data in the memory area of the smart card chip, as well as bringing security elements (passwords, access levels to different areas) to the state required by the client's technical task to solve business tasks.

Theoretically, hacking is possible, but this operation requires complex technologies and a large amount of time, which exceeds dozens of years. In addition, technology does not stand still and manufacturers of chips for smart cards, such as NXP, are constantly upgrading their chips, making them more difficult to protect.

Often, users themselves give access to their smart cards by mistake, disclosing the pin code or access passwords. Therefore, smart card manufacturers take these issues very seriously, creating clear procedures for storing and transmitting keys (passwords and pin codes).

Chip encoding on an industrial scale is performed on specialized equipment. As a rule, any complex coding tasks require individual software development and only a part of simple standard tasks can be performed “on the spot”. The electronic personalization procedure can be divided into the following stages:

(c) card-online.ru

- Selective varnishing

- Offset printing

- Digital printing

- Silk screen printing

- Embossment

- Indent printing

- Foil stamping

- Scratch bar

- Signature strip

- Printing variable data

- Barcode on plastic cards

- Magnetic Stripe

- Electronic personalization of smart cards

Selective varnishing

Types of graphic personalization on plastic cards

Technology of applying any selective image (logo, graphics, etc.) with a liquid varnish that polymerizes under the influence of UV rays with accurate contour preservation.

Selective varnishing is a popular method of elite finishing of plastic cards. Crystal glossy image allows you to enjoy the play of light highlighted design elements on discount, gift, business and other plastic cards.

An exquisite coating with various special effects makes a vivid impression on customers and business partners, leaving pleasant associations about your company.

Selective varnishing options (effects)

The variety of textures obtained during varnishing does not limit your imagination - depending on the design idea, you can apply a selective varnish with effects:- luxury gloss;

- velvety matte finish;

- multi-colored mother-of-pearl glitter and 3D effects;

- a fluorescent glow in the dark.

- luminescences - glow in ultraviolet light (to protect authenticity)

Layout requirements for selective varnishing

It is necessary to save the design elements for selective varnish on a separate layer in the layout program. Special varnishes with effects can be specified in the layout with some visual color that is not found anywhere else in the layout, for example, fill it with 100% magenta. Vector objects that represent the print area need to be trapped — set a contour to compensate for printing errors and avoid gaps.The paint outline must overlap the image by at least 0.3 mm.

The minimum thickness of the space element must not be less than 0.3 mm.

Our vast experience allows us to achieve excellent results and get a really voluminous varnish with a relief that is noticeable with tactile contact.

Offset printing

Printing technologies on plastic cards

The main technology for printing large print runs of all types of plastic cards. This method of printing is characterized by high clarity and brightness of a full-color image, obtaining even the smallest details of the drawing and high-quality micro-rifts.

How does offset printing work?

Offset printing uses an image transfer technique based on the repulsion of oil and water.The paint of the offset machine is fed to the offset shaft with photosensitive film (photo molds). The film serves as a template for transferring the layout image from one offset shaft to another, and then onto the plastic sheets of future cards.

UV - illuminated parts of the mold begin to attract water and repel any oily substance (paint). The remaining (unlit) parts of the forms begin, on the contrary, to repel water and attract paint. Thus, the paint is transferred only to the areas of the mold that are absorbed by water, forming letters and images.

The offset shaft contributes to less mold wear and greater evenness of the paint.

In offset technology, we use two printing methods with the use of:

- CMYK ink - full-color printing;

- mixed Pantone paints.

Colorfulness of the image-CMYK or Pantone?

Any color in full-color printing (CMYK) is achieved by mixing 3 colors (triad) of the main color-cyan( Cyan), magenta( Magenta), yellow (Yellow) and key color (KEY), usually black (Black).

It is with full-color printing (CMYK) that you can get a realistic image with a large number of shades.

CMYK colors always require the use of four photo forms, and sometimes additional forms for obtaining plastic cards with increased requirements for visual characteristics. When the exact color of a uniform fill is required to reduce the cost of photo forms, Pantone mixed paints come to the rescue.

Pantone-derived paints allow you to get colors and shades of certain areas of the spectrum (blue, green, brown) that go beyond the CMYK color range, which is widely used by companies around the world to brand their products or logos with the "corporate" color. Pantone mixed paints are tinted in advance by the number in the catalog and come to us ready-made, eliminating errors in obtaining colors from the four colors on the cards, and saving on color tests. Competent and skillful use of such tools as mixed paints by the designer can both reduce costs (in some cases) and get a visually more spectacular result.

Our design department can advise you on how to correctly and skillfully use ink in offset printing and prevent unnecessary costs. To get an excellent result, we will help you take into account all the subtleties of the technology when developing a layout and preparing an order for printing.

Digital printing

Printing technologies on plastic cards

Fast printing of high-quality images (text, graphics,drawings, photos) to a plastic card directly from a computer system without prepress preparation.

Advantages of digital printing

Digital printing provides excellent image quality, minimizing costs and reducing the time required to complete plastic card orders in small print runs.Plastic cards are printed on inkjet printers and have a number of advantages:

- low production costs for small print runs;

- ability to quickly print an average print run in a short period of time;

- simplicity of the technological process that does not require additional equipment and pre-printing preparation (color separation, mold making and adjustment, as in offset;

- high print quality;

- ability to quickly print a test sample;

- if necessary, you can quickly edit the layout, for example, adjust the color in place;

- ability to perform personalization (print personal data).

Disadvantages of digital printing

- Unprofitability when ordering large print runs (offset printing is more profitable);

- You can't use the Pantone palette, silver or gold colors.

- Restrictions on getting a deep black or dark blue color.

Silk screen printing

Printing technologies on plastic cards

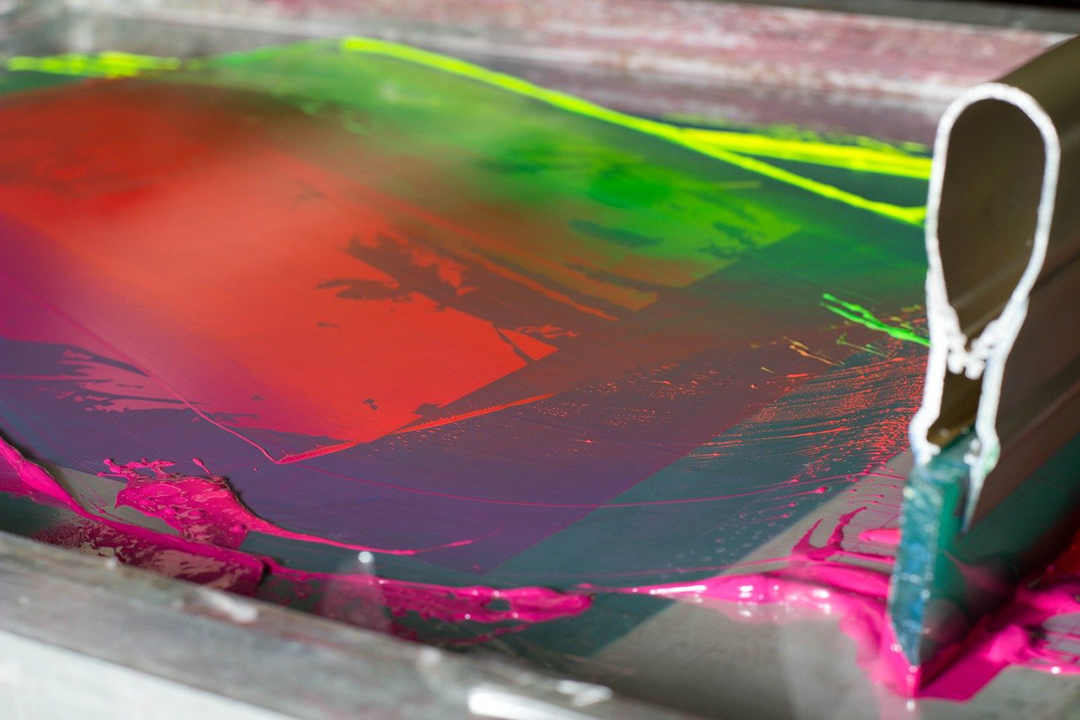

Silk screen printing (silkscreen printing) - screen printing, in which” layers " of paint are applied to the surface using a squeegee through a screen grid.

We use silkscreen printing to create spectacular relief images (logos, graphics, etc.) and backgrounds on your plastic cards, as well as for applying selective varnishing, signature strips, and scratch panels.

How it works

We apply a layer of photoemulsion to the screen grid and light the grid in a special device with a UV lamp.In those places where the paint should not pass in the illuminated grid , a film is formed that serves as a stencil for us. The grid is washed off with plain water, dried and installed on the equipment for running paint with a rubber squeegee.

By rearranging the grids with different colors, we achieve the final result - getting another bright masterpiece inherent in silkscreen printing.

What is the power of silkscreen printing?

The main advantage of this method is the ability to change the thickness of the paint application, achieving a stunning relief image that is noticeable upon contact. At the same time, the image remains stable and bright for a long time.The silk screen printing machine allows you to paint sheet plastic in any desired color, which is then printed with CMYK or Pantone paints.

Most often, interesting backgrounds for your plastic cards are achieved in this way - metal backgrounds of different colors and shades, gold, silver, mother-of-pearl, with 3D effects, glow-in-the-dark and thermochromic, changing their color depending on the temperature.

Disadvantages of the technology

- Stencil printing can achieve a resolution of no more than 90 dpi

(dots per inch); - It is not advisable to print small print runs;

- Complex transmission of color gradients.

Embossment

Types of graphic personalization on plastic cards

Embossing is the process of mechanically squeezing out various information on the front side of a plastic card (the last name, first name and patronymic of the holder, validity period, card number, company name (for corporate clients)).

Your corporate identity protection and support

The process of embossing refers to the type of personalization and is performed on all types of cards - discount, bonus, club, insurance club, etc.A stylish card decorated with various emblems, iridescent embossed signs, inscriptions made up of convex shiny symbols can serve not only as its protection, but also become a bright addition to the design of the company's corporate identity.

How is embossing performed?

Embossing is performed on ready-made (laminated and cut) plastic cards. To extrude identification information on plastic cards, special devices are used — embossers (English embosser).Automatic embossers are a complex technical complex that includes a microcomputer that controls a drum with a set of letters (Cyrillic, Latin or numerals), through which images on plastic cards are squeezed out.

The productivity of such devices can reach several hundred personalizations per hour.

The process is strictly regulated and has clear requirements.

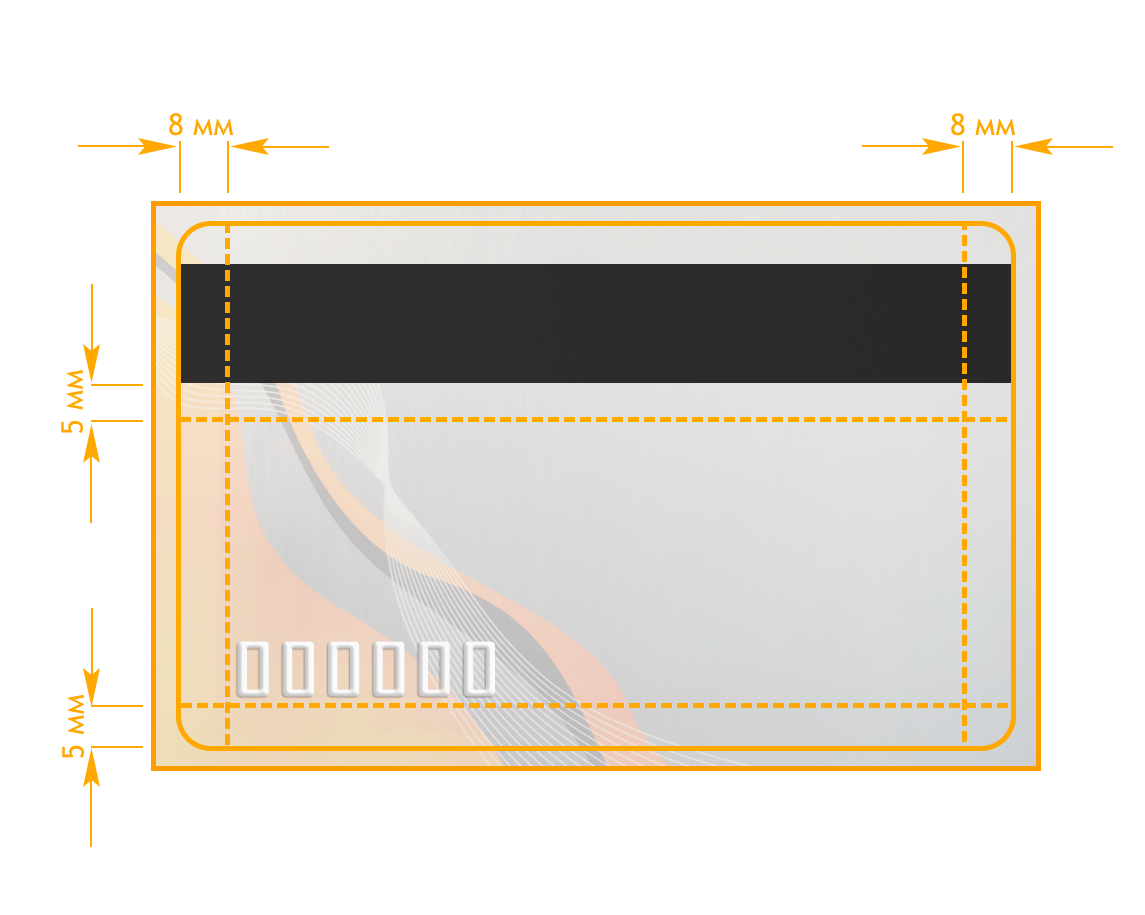

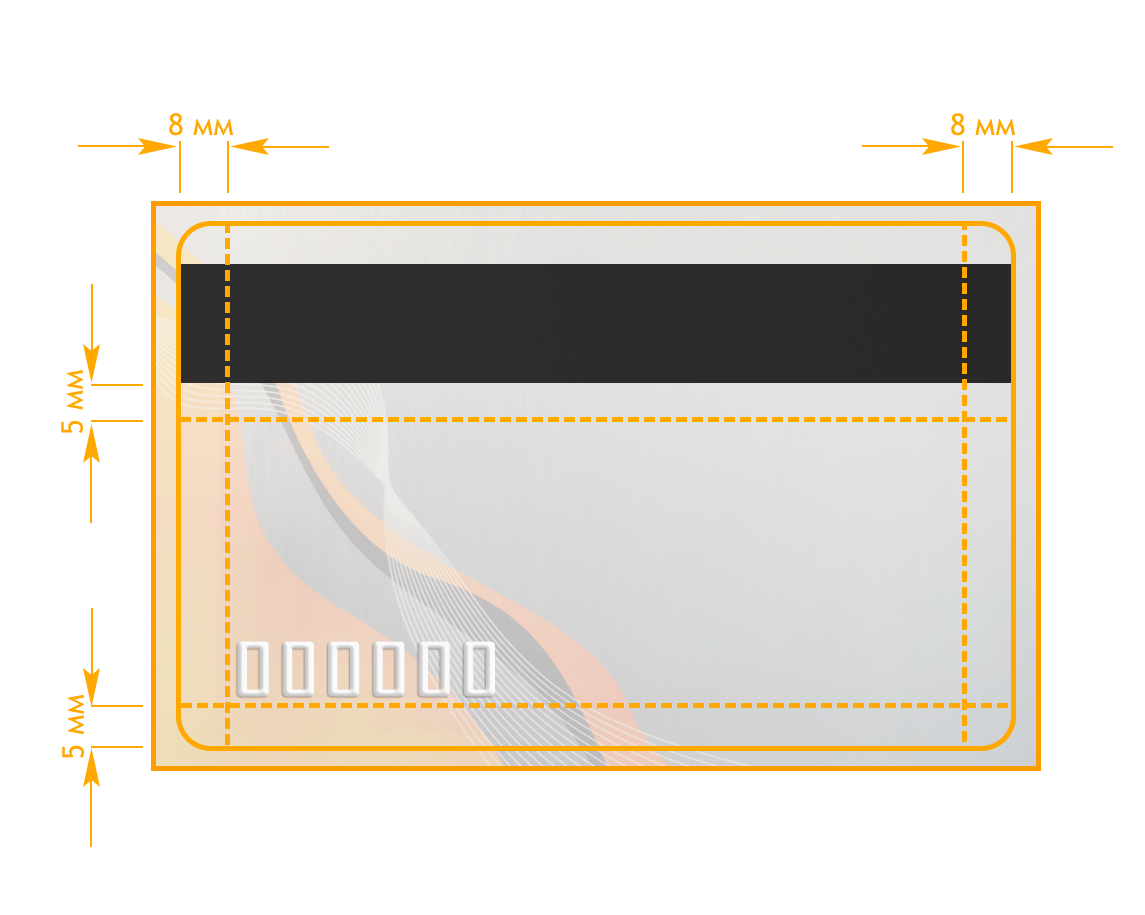

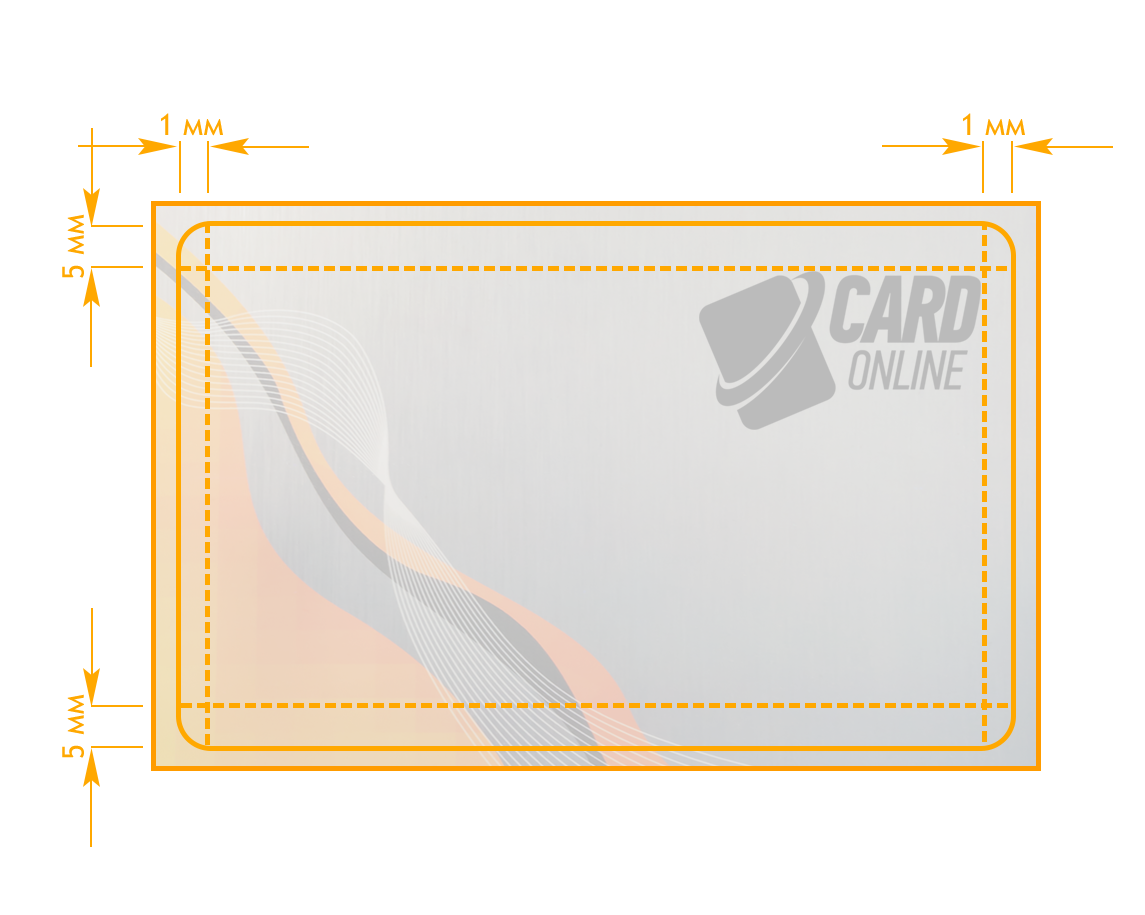

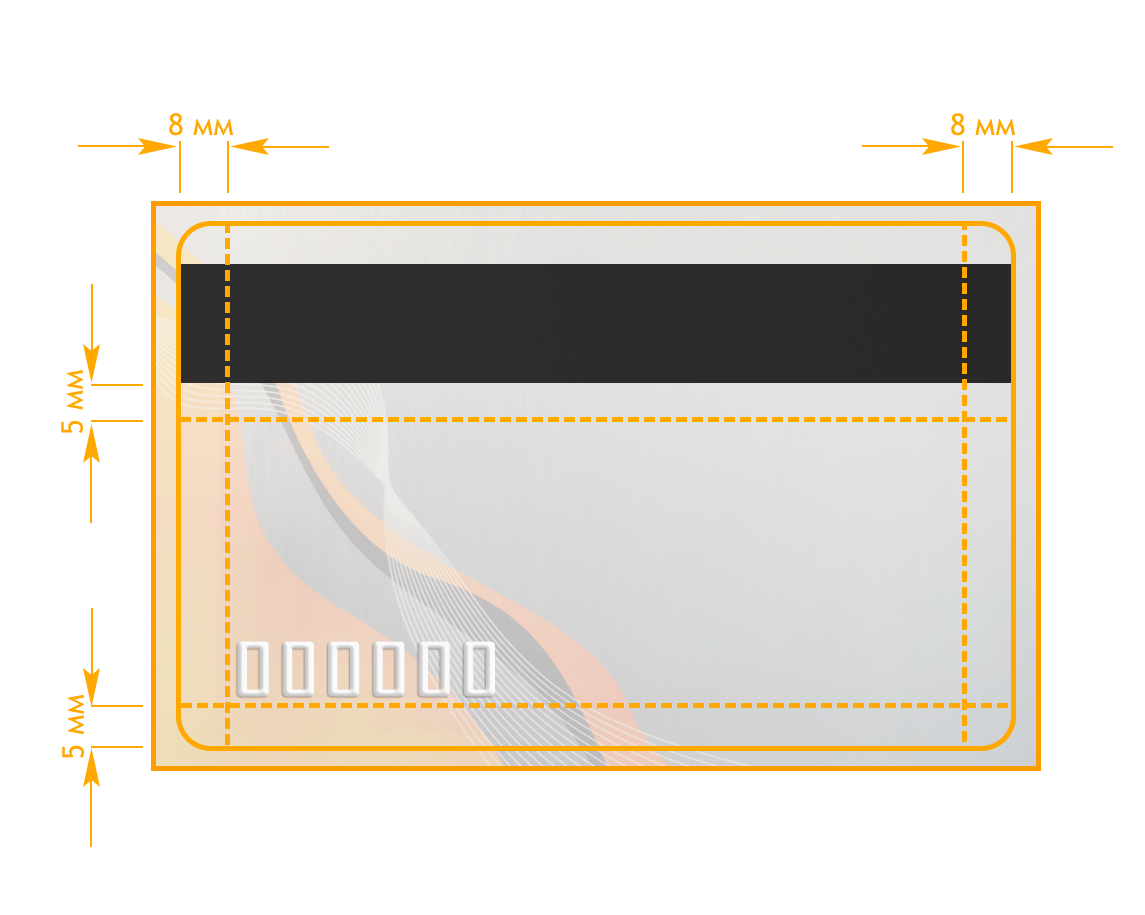

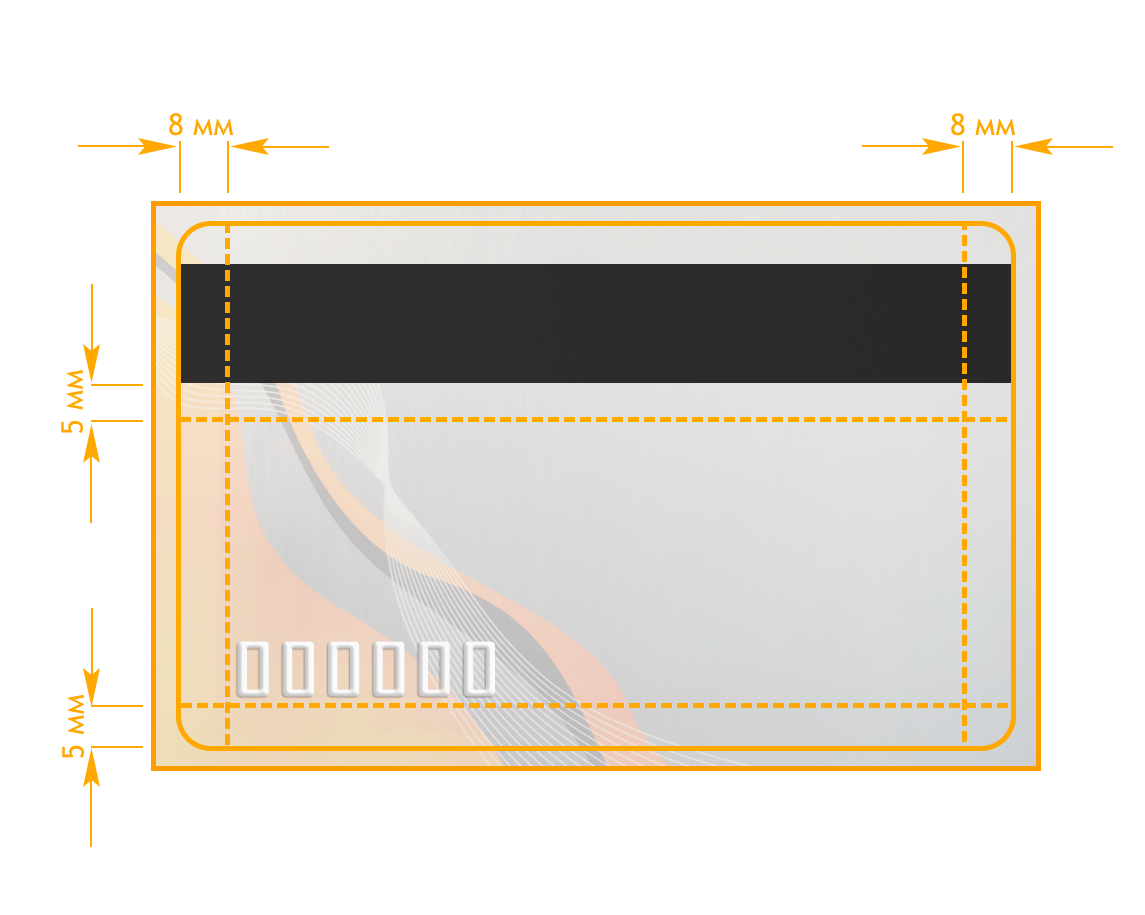

Requirements for embossing

The symbols stamped on the card must be located on the card at a distance of at least 5 mm from the top, at least 5 mm from the bottom edge of the card, and at a distance of at least 8 mm from the left and right edges of the card. The distance from the magnetic strip should not be less than 5 mm.

When you emboss characters, they are only pressed horizontally and have a standard font size of 3.5 x 4.5 mm and 2.5 x 3 mm.

A large font can only contain numbers: 0123456789

Small font - numbers and uppercase letters of the English alphabet, including symbols: ".", ",", " ’", "-", "/", "&"

The number of characters in one line is:

- for a large font (Standard Gothic and Cyrillic, Caard Standard) 4.5 mm - 20 characters.

- for a small font (OCR 7B, Caard Large Numbers) of 3 mm - 26 characters.

Pressed letters and numbers can be colored in color, this procedure is called "typing". For tipping, gold or silver foil is most often used, less often black or white, but other colors are also possible.

Requirements for embedding with typing

According to the ISO 7811 standards, when coloring (typing) characters, the location of the embossed characters is determined more strictly at least:- 8 mm from the left;

- 5 mm from the bottom;

- 5 mm from the right edge of the card.

- The maximum distance from the bottom edge of the card to the top of the emboss area should be 24 mm.

Indent printing

Types of graphic personalization on plastic cards

Mechanical indentation of variable data (expiration date, card number) on the front side of a plastic card, usually with further coloring (tipping) in black or white.

Indent seal - Your protection against counterfeiting

The indent printing process refers to a type of graphic personalization and is performed on any type of card - discount, bonus, club, insurance club, etc. and serves as an identifier of the card holder and its protection against counterfeiting.For the best solution of your tasks, you can combine the types of personalization.

Indent printing process

Indent printing is performed on ready-made (laminated and cut-out) plastic cards on special devices (embossers) using the same technology as embossing, but with the opposite effect. The pressed-out symbols do not protrude above the card surface, but rather are pressed into the plastic.Requirements for indent printing

Indented symbols must be located on the card at a distance of at least 5 mm from the top, at least 5 mm from the bottom edge of the card, and at a distance of at least 8 mm from the left and right edges of the card. The distance from the magnetic strip should be at least 5 mm.

When indent printing, characters are pressed only horizontally and have a standard font size of 3.5 x 4.5 mm and 2.5 x 3 mm.

A large font can only contain numbers: 0123456789

Small font - numbers and uppercase letters of the English alphabet, including symbols: ".", ",", " ’", "-", "/", "&"

The number of characters in one line is:

- for a large font (Standard Gothic and Cyrillic, Caard Standard) 4.5 mm - 20 characters.

- for a small font (OCR 7B, Caard Large Numbers) of 3 mm - 26 characters.

Indented letters and numbers can be colored. This procedure is called "typing". For tipping, black or white foil is most often used.

Foil stamping

Types of graphic personalization on plastic cards

The technology of applying a selective image with ordinary or holographic foil, to get a metallic luster of various colors and shades (gold, silver, etc.) and give a luxurious appearance to your corporate identity on the card.

Metallic elements of the impression (logo, company name) attract attention, and the relief that can be obtained by hot stamping emphasizes their sophistication, which makes it possible to effectively highlight parts of the image containing important information.

Embossing refers to the post-printing finishing of products and is already done on the finished (laminated) surface of the card.

How is embossing performed?

Hot stamping is performed on special automatic presses. A metal cliche is attached to one side of the press.Foil is placed between the stamp and the plastic card. The cliche is heated to the desired temperature and pressed against the foil under the influence of strong pressure.

The visual possibilities of embossing are very wide-combinations of different textures, colors and types of foil provide a huge number of original design options.

.jpg)

View all kinds of cards

Choose your own color and texture just for your unique style!

Holographic foil is becoming increasingly popular in the decoration of plastic cards. It has mechanical resistance and opacity. It is used to give prints a memorable look and increase the degree of protection against forgery.

Imitation of embossing

For small print runs, it is more profitable to replace the stamping with sublimation printing with metallized foil. As a rule, customers highlight numbers, symbols, and letters (in gold or silver). The quality of this method is slightly inferior to hot stamping, sublimation printing is not as durable in use as with hot foil pressing, but it saves the cost of cliches.

Foil stamping requirements

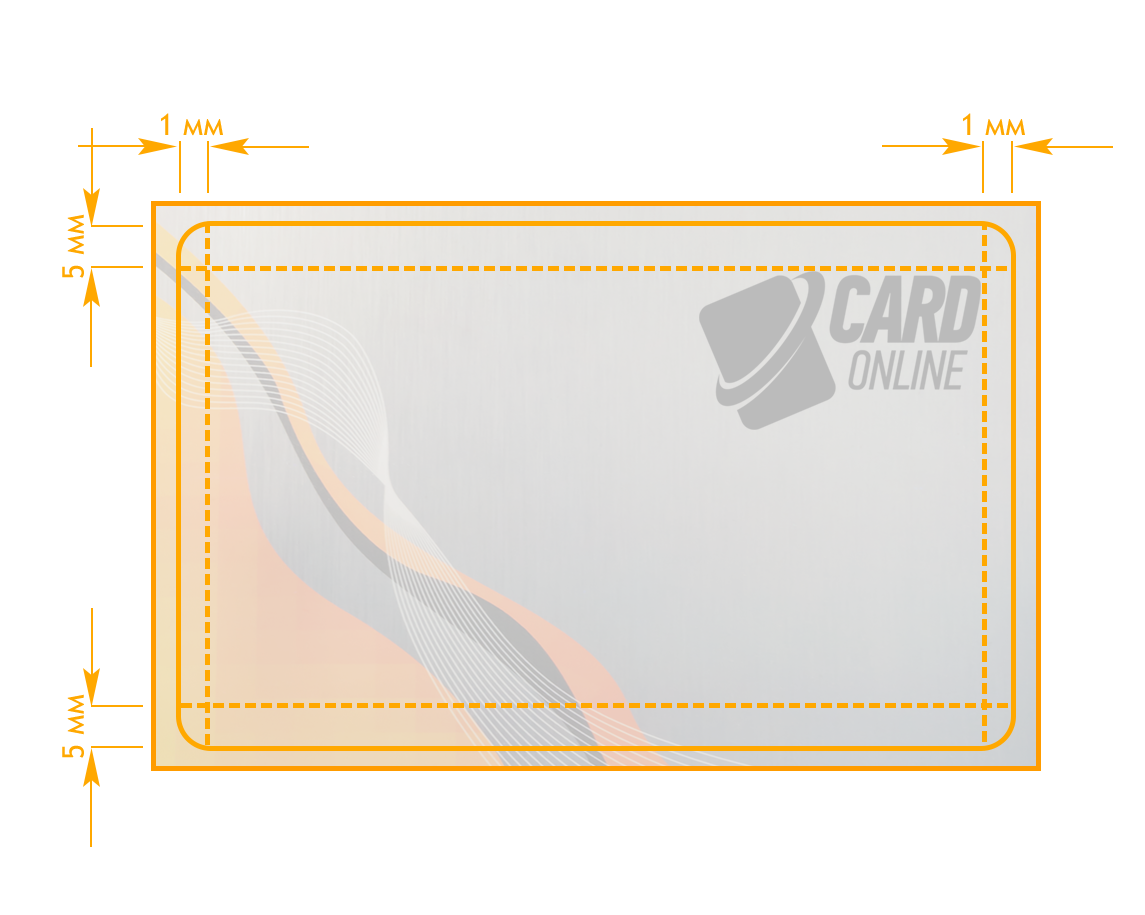

For regular foil stamping, when placing an item in the layout, you need to take into account the field on the card, the indent should be:

- at least 5 mm from the top and bottom edges of the card;

- at least 1 mm from the left and right edges;

- with a minimum line thickness of 0.3 mm,

For stamping with holographic foil, it is necessary to position each hologram more clearly relative to the image before printing with an accuracy of 0.1-0.2 mm.

Therefore, special presses with complex drive control systems are used for their pripressovki. Accuracy is achieved by using labels on the foil.

When you emboss text, there is a font size limit. For personalization elements, you must specify the font name, font style, and size. The text must be at least 6 pt (for the Bold style), and at least 10 pt (for the Normal style).

Stamping is used on plastic cards with a thickness of 0.65-0.84 mm. Embossing on thin cards can cause it to slightly deform.

Scratch bar

Types of graphic personalization on plastic cards

A special layer on a plastic card that protects secret data: text (code or word), drawing.Information under the scratch strip is only available when it is destroyed (erased).

Play and win!

Printing cards with a scratch panel is a low-cost way to issue large-circulation cards for prepaid services, cellular communications, IP telephony, the Internet, and lottery tickets.Intrigue for customers under the erasable scratch card layer in a new promotion in an exciting way will be a win for your business. It will attract customers and create a loyal customer base, increasing the firm's revenue.

Use different forms of scratch fields on your cards to make your client more interested.

How to apply a scratch field

Scratch coating is applied in two ways: silk screen printing with special ink and scratch stickers.

Applying a scratch layer with paint

When applying a strip by silk-screen method, the shape and number of scratch fields is determined only by your imagination.The complexity of the pattern does not affect the cost of work. The price increases only if the scratch field increases by more than 30% due to additional paint consumption.

Using a scratch sticker

Stickers (scratch panels) are more expensive than scratch paint, because in addition to the cost of paint and substrate, additional work on cutting, packaging and gluing stickers is included.Layout requirements

The font and size of the scratch strip can be any.

- the distance from the card edge is at least 2 mm.

- the fields must be positioned horizontally.

How to reduce costs

To save money, use a plastic thickness less than the standard (0.33 mm, 0.55 mm) with subsequent varnishing.Our experts will help you choose the best way to apply a scratch strip.

Signature strip

Types of graphic personalization on plastic cards

A special strip is designed for writing a signature sample and other personal information with a ballpoint pen, which serves as an additional protection for the card when identifying its owner.

Opportunities for using the signature strip

The band got its name “for signature", because it was previously used exclusively for signing on bank cards. Due to the fact that the pen can write any personal data (about the car owner, document number, etc.), the strip is relevant for all types of cards (discount, bonus, club, insurance) both independently and in combination with other types of personalization.

Important to know

We can create a special layer of any configuration, almost all over the card surface on both sides, with the following restrictions:

- 4 mm indent from each edge of the card

- padding of at least 4 mm to the magnetic strip

On cards with a magnetic stripe, do not place the signature panel in the rental area of the reader head - this may lead to clogging of the reader and damage to the signature strip itself.

Ways to apply a signature strip

There are three ways to apply signature strips to a card: silk-screen printing, hot stamping, and sublimation printing.- When silk-screen printing, strips of ink are applied through a stencil, as with conventional silk-screen printing, only using special ink on laminated card blanks. This method is the most common, due to its capabilities and affordable price for large print runs. You can use it to print a strip of any shape, make it white or transparent. You can place any image on the transparent bar, making it a design element and inaccessible for erasure. The quality of the signature screen strip is the highest we offer. You can write on such a strip with any pen, and the process is pleasant and accurate.

- Applying the strip in a hot way, as with the usual method of embossing, occurs on a press using a cliche, only with a special or simply matte foil. The application process is faster than screen printing.

- The strip applied by sublimation printing is formed by ink transferred from the film to the laminate surface. The advantages of this method are that the stripe can be made of any size and applied anywhere on the card without indentation in the amount of one piece or more, without additional preparation costs. It is characterized by low speed and expensive consumables. Suitable for small print runs and samples.

Printing variable data

Types of graphic personalization on plastic cards

Print individual variable data (last name,first name, card number, date of birth, position,phone number) on the card surface to identify the owner.

Variable data is relevant when using discount, bonus, club cards, badges, and passes.

How variable information is printed

Individual information can be printed by sublimation, drop-jet printing, or a modern DoD printer with UV ink.Sublimation printing is traditionally the most expensive and less productive, but setting up the equipment takes only a few minutes, which makes this method optimal for small and urgent print runs.

If we are talking about several tens or hundreds of thousands of cards, then drip-jet and DoD printing come to the rescue.

Drop-jet marking is performed by a drop-jet printer at very high speeds. This method is used to plot, for example, the date of manufacture of food products. A characteristic feature of this method is the visible dots that make up the symbols.

DoD printing is done with an expensive personalization package. Inks that harden under UV light are used, which makes the image resistant to any mechanical and chemical influences, unlike the above methods, the image of which can be erased over time.

Each card can contain an unlimited amount of variable information. End-to-end variable data (1-2-3-4-5, etc.) can be specified with a range. For example: 0001-0500.

More complex variables (out of order or multiple corresponding variables) must be provided as an Excel electronic database.

Barcode on plastic cards

Types of graphic personalization on plastic cards

Small-volume graphic information on plastic cards for customer identification. Easily read by all kinds of scanners and apps in your phone.

Your corporate identity protection and support

The linear barcode on plastic cards is used by the sales system to determine the price or discount for a specific customer, which saves time and makes the work more convenient. Automated flow at the checkout does not cloud the customer's expectation when entering data into the computer manually and helps to avoid errors and typos for the seller. The PIN code on the plastic card, like the entire image, is reliably protected from mechanical damage.Types of barcodes and what they are eaten with

There are more than 300 types of linear barcodes.Plastic cards most often display a barcode: EAN-13, EAN-8, Code-39, Code-128. The choice of the appropriate option depends on your card usage conditions.

A barcode can be applied using any printing method and encoded in only one direction (in width, the more information, the wider the barcode).

The amount of information in a linear barcode does not affect the height of the barcode. However, the higher the barcode, the more likely it is to be read the first time.

It is possible to place the barcode on the card in horizontal and vertical versions and stripes of contrasting colors depending on the selected design. Printing in black on a white or red background provides a more stable reading experience.

We can help you determine the type of barcode that is convenient for your account system. For consultation and ordering, please contact our managers online.

Which barcode should you choose?

EAN - 8 and EAN-13 barcodes

The most common type of barcode. When they say that a product has been assigned a barcode, they are talking about a barcode of the EAN-13 type. For very small items, the EAN-8 type is used.EAN 8

Used instead of ELAN 13 if there is not enough space on the card. You can write a 7-digit number, and the 8th digit is a control number.

EAN 13

The most popular format. You can write a 12-digit number, and the 13th digit is a control number.

CODE 128 and CODE 39 barcodes

CODE 128 is one of the most convenient ones. It allows you to encode very compactly long sequences of digits (a pair of digits is encoded as a single character). It can encode not only numbers, but also symbols.CODE 39 is a widely used barcode. Demanding of free space.

CODE 128

You can encode from 1 to 70 characters. You can use Latin letters (from A to Z from a to z), numbers (from 1 to 0), and special characters:

(! @ # $ % ^ * ( ) - + = _ |\/ [ ] { } . , ; :' ` " )

CODE 39

You can encode from 1 to 43 characters. You can use Latin letters (from A to Z), numbers

(from 1 to 0), and special characters:

(+ - . % $ space)

Attention: when developing the layout, you need to specify the location for placing the barcode in the form of a white rectangle. If the card background is light, then you can mark the card without using a white background. The barcode size must be at least 34 x 14 mm and no closer than 2.5-5 mm from the edge of the card.

Magnetic Stripe

Types of electronic personalization on plastic cards

Flexible tape for storing data (data storage medium) serving as a cardholder identifier.

The magnetic stripe is programmed for specific tasks and is easily read using standard devices (card readers) that can transfer data to a computer in 1 second.

Sometimes card readers are programmed using an algorithm that differs from the standard one. In this case, the device can only read information from certain cards that use the same algorithm for recording.

Scope of application of the magnetic strip

Convenient and fast-reading plastic cards with a magnetic stripe are used in all areas of trade, services and access control systems.The stripe is applied to cards that meet ISO standards - discount, gift, social, business cards, electronic keys and identity cards of employees in organizations.

HiCo and LoCo magnetic strips.

Most often, two types of tape are used: HiCo (High - coercive - high - coercive = 2750 oersted) and LoCo (Low-Coercive-low-coercive = 300 oersted) magnetic strips. The difference between the bands is their magnetization strength. The Hi-Co strip is more reliable and durable, as it is less susceptible to demagnetization and therefore costs more.Your data is stored on it longer than on the Lo-Co band under the same conditions of use, so they are plotted on cards designed for long-term and frequent use.

The Lo-Co band is usually used on temporary access cards, for example, in hotels as electronic keys. Lo-Co card magnetization requires less expensive equipment. It is noted that magnetic bands with low coercivity are colored light brown, and bands with high coercivity are almost black.

Although the color of the strip can be any, it depends on the manufacturer of the tape. The color does not affect the quality. You don't have to limit your imagination, we are ready to make a card with a silver, gold, blue, red, and green stripe for you.

Magnetic tape encoding

Magnetic tape encoding is performed by magnetizing tiny particles located on the surface of the strip using the magnetic head of the encoding device.Data is written (or encoded) to the card at the client's request once and is not rewritten again.

In plastic discount cards or electronic keys, either one second track is used, or the first and second. All three tracks are mainly used on banking system cards.

The band is encoded with:

- code of the company that issued the plastic card;

- card number;

- card expiration date.

| Start of recording | Encoded characters | Number of characters | End of recording | |

| Track 1 | % | 0-9 A-Z . , : ; ! ' / = ( ) ! @ # ^ & * < > / | 76 | ? |

| Track 2 | ; | 0 1 2 3 4 5 6 7 8 9 = | 37 | ? |

| Track 3 | _ | 0 1 2 3 4 5 6 7 8 9 = | 104 | ? |

Layout requirements

For standard readers, the magnetic stripe is made 12.7 mm wide. According to the ISO-7811 quality standard, you can also use a narrow, 6.35 mm magnetic strip, but a narrow strip is cheaper because you can only record the second track on it.

Both strips can be positioned strictly 4 mm from the upper and lower edges in a horizontal position.

Electronic personalization of smart cards

Types of electronic personalization on plastic cards

Electronic personalization - recording individual data in the memory area of the smart card chip, as well as bringing security elements (passwords, access levels to different areas) to the state required by the client's technical task to solve business tasks.

Your reliable protection

Data on a modern smart card is encrypted using complex digital codes, it cannot be copied or read by a simple skimmer, it is stored for about 10 years and is not subject to demagnetization.Theoretically, hacking is possible, but this operation requires complex technologies and a large amount of time, which exceeds dozens of years. In addition, technology does not stand still and manufacturers of chips for smart cards, such as NXP, are constantly upgrading their chips, making them more difficult to protect.

Often, users themselves give access to their smart cards by mistake, disclosing the pin code or access passwords. Therefore, smart card manufacturers take these issues very seriously, creating clear procedures for storing and transmitting keys (passwords and pin codes).

How the encoding is performed

Chip encoding on an industrial scale is performed on specialized equipment. As a rule, any complex coding tasks require individual software development and only a part of simple standard tasks can be performed “on the spot”. The electronic personalization procedure can be divided into the following stages:

- The card is taken out of the feed tray and moved to the smart card recorder;

- Directly encoding, can take from a few fractions of seconds, up to 2-3 seconds when recording a large amount of information;

- Applying graphic personalization;

- Automatic quality control systems.

(c) card-online.ru